Could a single material truly revolutionize industries, enhancing both efficiency and the lifespan of critical components? The answer lies within the remarkable properties of Micarta and similar industrial laminates, materials that have become indispensable across a wide spectrum of applications.

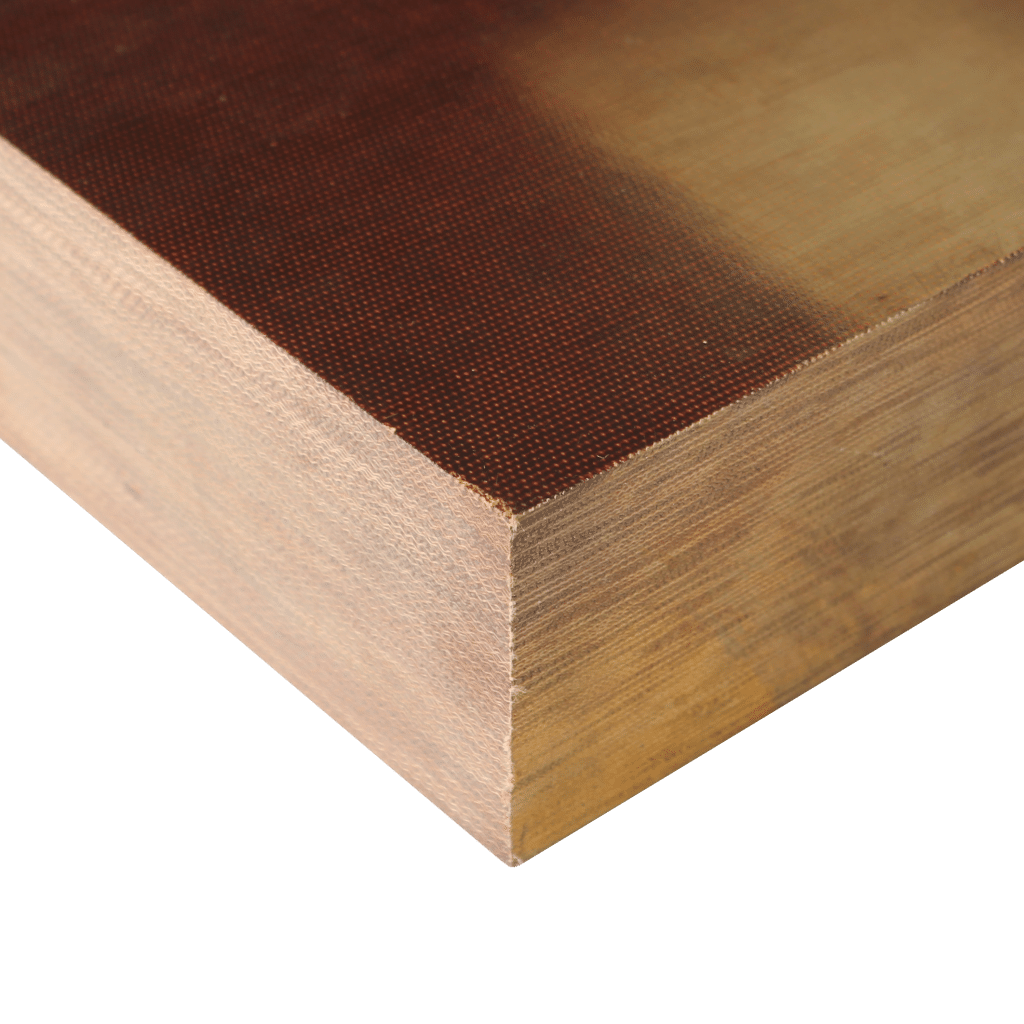

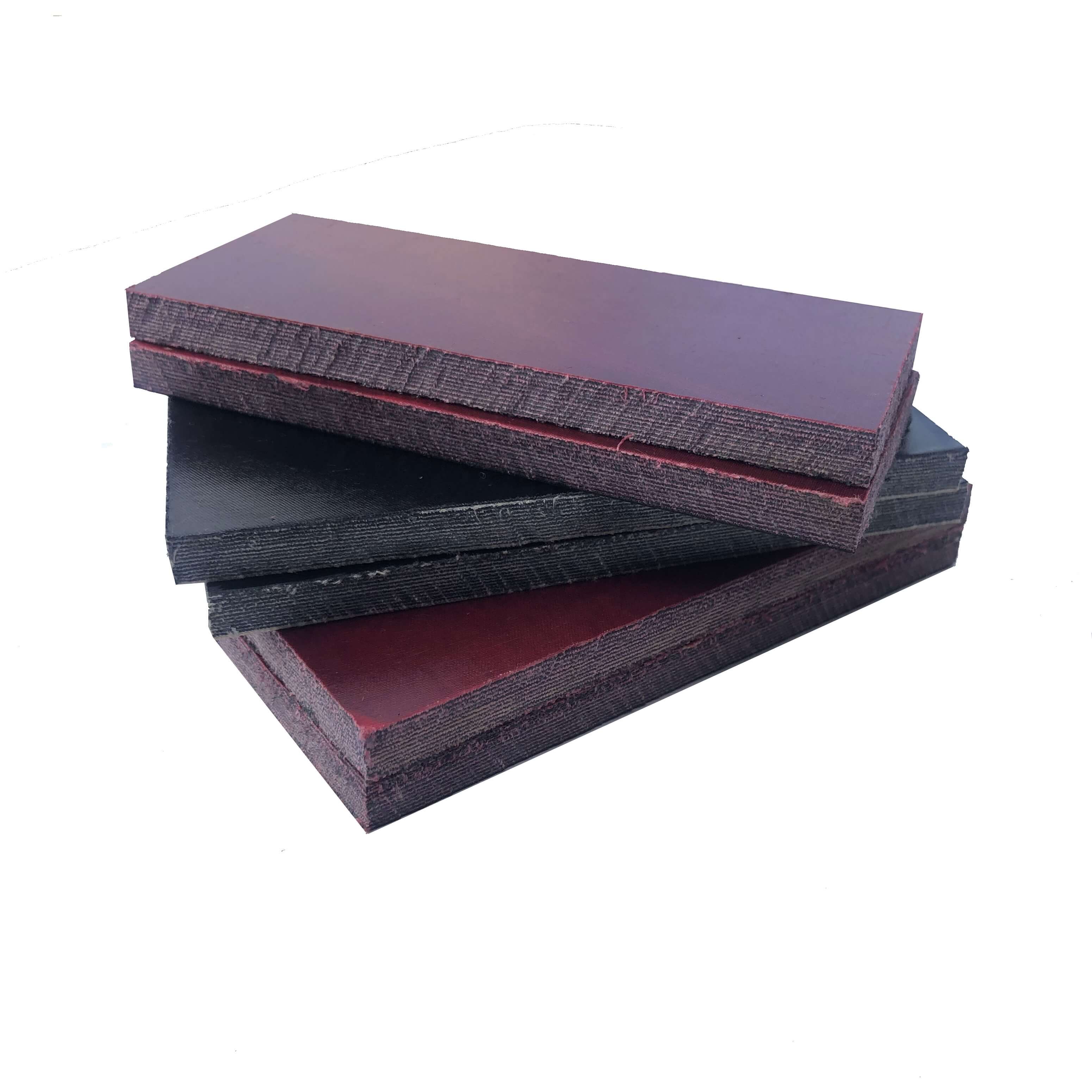

Micarta industrial laminates are not just another material; they represent the pinnacle of phenolic thermoset materials. This is a strong claim, backed by years of proven performance and a versatility that is hard to match. Manufactured through a process involving heat and pressure applied to layers of paper or glass cloth infused with synthetic resin, Micarta phenolic sheet is a hard, dense substance. This unique composition grants it an array of impressive qualities, including high dielectric strength, resistance to heat, and robust mechanical characteristics. These properties make it a preferred choice in demanding environments. From aerospace to electrical insulation, its applications continue to broaden, solidifying its position as a vital component in modern manufacturing.

This material's effectiveness spans various project phases, providing key advantages from procurement to installation and beyond. G10 Micarta supports, for instance, offer a streamlined manufacturing process, resulting in quicker fabrication turnarounds. Moreover, the engineered design of these materials extends to specialty applications like cryogenic systems, where their proven performance in energy, aerospace, medical, and scientific markets is invaluable. The scope of these products extends to cover a full range of thermoset composites for electrical insulation and electrostatic discharge (ESD) applications, further cementing their status in the industry.

- Boost Creativity Collaborative Writing Game For Students

- Uncovering Christopher Fredericks Details Age Net Worth More

Phenolic plastic, often recognized by its brand name Micarta, presents a compelling blend of qualities, being both lightweight and exceptionally strong. It resists deterioration and provides a remarkable ability to withstand heat. Acme Plastics, along with other manufacturers, caters to the diverse needs of the market by offering phenolic products in various shapes, sizes, and colors. This customization capability is essential for meeting the unique requirements of different projects. Whether it's about barriers, breaker arms, or switch panel boards, the material has proven itself in numerous applications.

The formulation of Micarta involves various resin systems such as phenolic, silicone, melamine, and epoxies, along with substrate materials ranging from paper and cotton to glass. This flexibility allows for the development of customized solutions tailored to specific requirements. The products usability in both dry and high-humidity environments adds to its practicality, establishing its versatility across a broad range of industries and applications.

The versatility of Micarta and similar industrial laminates makes it a key material in numerous industries. Beyond its well-known use in electrical insulation, it is prevalent in aerospace, automotive, marine, and heavy equipment sectors. It is also a staple in steel and paper industries, showcasing its adaptability. The material's ability to endure high stress and corrosive chemicals makes it a reliable choice for harsh environments. Additionally, Micarta is not only used in high-strength electrical insulation but also in power generation and distribution equipment.

- Steak Cooking Temperatures Your Guide To Perfect Doneness

- How Tall Is Jared Padalecki His Height More

Micartas versatility is further exemplified by the different forms in which it is available. Offered in sheets, rods, and tubes, it can be adapted to numerous applications. The construction of Micarta involves a base reinforcement material that is laminated using several resin systems. This type of construction allows manufacturers to make materials with specific properties that cater to a variety of needs. The availability of Micarta in different shapes and panels, comparable to other building materials, simplifies its integration into various designs.

The brand name Micarta represents a variety of composite materials featuring diverse fibers embedded in thermosetting plastics. These materials may include linen, canvas, paper, fiberglass, carbon fiber, or other fabrics. These materials are often utilized in electrical and decorative applications.

Specific grades, like Np630 (NEMA XXX), provide a machining grade with excellent electrical properties and high moisture resistance. Np130, another popular variant, is made of woven glass fabric combined with a halogenated epoxy resin system and conforms to printed circuit board quality standards. These variations emphasize the diversity of Micartas applications, showcasing its adaptability and precision.

The manufacturing process is vital to the quality of Micarta. Using excellent insulating materials with high creep resistance is crucial for withstanding extreme compressive forces in high-temperature environments. The utilization of transformer board material for electrical insulation is a testament to its effectiveness. Moreover, distributors of transformer board material offer further support to the industry.

For cryogenic applications, thermoset composite materials serve a vital role in cryogenic pipeline insulation and support, as well as in cryogenic storage vessels, bunkering tanks, and LNG carriers. These applications show Micartas capability to meet specific demands.

The careful selection of materials and the precise application of manufacturing techniques guarantee the reliability and performance of Micarta in various industries. The expertise of dielectric manufacturing experts plays a key role in ensuring that these materials are applied effectively. This collaboration further enhances the usability of Micarta and related materials, ensuring they meet the requirements of demanding applications.

The key to a product's effectiveness often lies in the design and the selection of appropriate materials. The properties of Micarta, such as its durability and ability to handle stress, make it ideal for several applications. The versatility of Micarta, whether used in knife handles or industrial equipment, is a sign of its importance in manufacturing. Its properties have consistently proven themselves to be an ideal choice for various applications, making it an essential material in multiple industries.

The ability of Micarta to excel under extreme conditions, such as in high-temperature environments, underlines its ability to withstand rigorous usage. Materials with maximum creep resistance are critical in withstanding extreme compressive forces in such settings, ensuring both generators and transformers operate safely and efficiently.

The continued development of Micarta and related materials indicates that the industry is committed to innovation and meeting the evolving needs of different sectors. The selection of materials to meet specific requirements is essential. By using quality materials, products can be constructed to provide optimal performance and durability.

Moreover, the availability of various forms, from sheets to tubes, underscores Micartas adaptability to a wide range of design specifications. The manufacturing and distribution of such a versatile product requires stringent standards. This adaptability is a key factor in its widespread use across different industries.

From high-strength electrical insulation to applications in aerospace and automotive, Micartas consistent performance is a testament to its design and manufacturing. As technology advances, this material continues to play a crucial role in various sectors.

The combination of heat, pressure, and synthetic resin gives rise to the Micarta material, which excels in a wide array of uses. The product is the best choice because of its strength, resistance to chemicals, and electrical properties. The careful selection of materials and application of production techniques guarantees its reliability. With continued research, Micarta and related materials remain vital for innovation and for meeting industry needs.

Detail Author:

- Name : Mr. Frederic Larkin I

- Username : dangelo.nicolas

- Email : nicolette87@hotmail.com

- Birthdate : 1978-06-20

- Address : 72080 Astrid Shoal North Albertha, KY 72811

- Phone : (725) 392-0614

- Company : Buckridge LLC

- Job : Animal Care Workers

- Bio : Quod voluptas sint nobis laborum. Vel velit ratione eum non perferendis minus. Nihil rem voluptatem consequuntur sapiente. Eum exercitationem dolor ratione.

Socials

twitter:

- url : https://twitter.com/providenci_xx

- username : providenci_xx

- bio : Et enim incidunt neque et ducimus. Fugit molestias totam numquam et qui dolor. Eveniet velit voluptatem quia.

- followers : 3256

- following : 1095

instagram:

- url : https://instagram.com/providencischneider

- username : providencischneider

- bio : Ducimus vitae eum et velit ab. Exercitationem quia est maiores quo.

- followers : 6991

- following : 1098

linkedin:

- url : https://linkedin.com/in/providenci_xx

- username : providenci_xx

- bio : Nisi molestias eius ad ut distinctio.

- followers : 3929

- following : 1331

tiktok:

- url : https://tiktok.com/@providenci_schneider

- username : providenci_schneider

- bio : Incidunt temporibus laborum quia sint.

- followers : 6256

- following : 2891

facebook:

- url : https://facebook.com/providenci_id

- username : providenci_id

- bio : Molestiae et saepe accusamus hic.

- followers : 6922

- following : 546